Design to Launch Services

Fisher Barton’s Design to Launch services provide comprehensive support for medical device development, ensuring precision, reliability, and innovation from concept to production. Leveraging advanced engineering expertise, Fisher Barton collaborates with healthcare manufacturers to optimize materials, coatings, and performance characteristics, enhancing product durability and functionality. Their streamlined approach accelerates development timelines while maintaining strict industry standards, delivering customized solutions for surgical instruments, implants, and diagnostic equipment. With Fisher Barton’s expertise, medical professionals gain access to high-quality, cutting-edge technologies designed to improve patient care and operational efficiency.

Material Development

Fisher Barton’s material development expertise plays a crucial role in advancing medical device performance and longevity. By leveraging cutting-edge engineering and specialized coatings, they optimize materials to meet the stringent demands of the healthcare industry. Whether enhancing biocompatibility, improving wear resistance, or developing antimicrobial solutions, Fisher Barton ensures medical instruments, implants, and diagnostic equipment achieve superior durability and functionality. Their innovative approach supports precision manufacturing, helping medical professionals deliver high-quality patient care with reliable, next-generation technologies.Tech Center Link to https://www.fisherbarton.com/capabilities/technology-center/

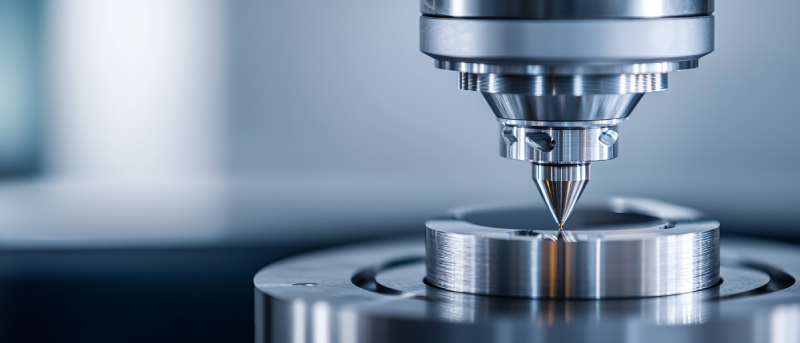

Process Development

Fisher Barton’s process development expertise ensures precision, efficiency, and innovation in medical device manufacturing. By leveraging advanced engineering, material science, and surface treatment technologies, they optimize production methods to enhance product performance and durability. Their tailored approach supports the stringent requirements of the medical industry, improving consistency and reliability for surgical instruments, implants, and diagnostic equipment. Through continuous improvement and cutting-edge solutions, Fisher Barton helps healthcare manufacturers streamline operations, reduce costs, and deliver high-quality technologies that advance patient care.

Quality Applications – Validation

Fisher Barton’s QA validations ensure the highest standards of quality, precision, and reliability across all aspects of medical device manufacturing. Through rigorous testing, compliance checks, and advanced validation processes, they confirm that materials, coatings, and engineered solutions meet stringent industry and regulatory requirements. Their comprehensive approach enhances product consistency, durability, and performance, supporting healthcare professionals with dependable technologies that prioritize patient safety. By integrating thorough inspections and continuous improvement strategies, Fisher Barton delivers cutting-edge medical innovations with confidence and excellence.